Limes Laser

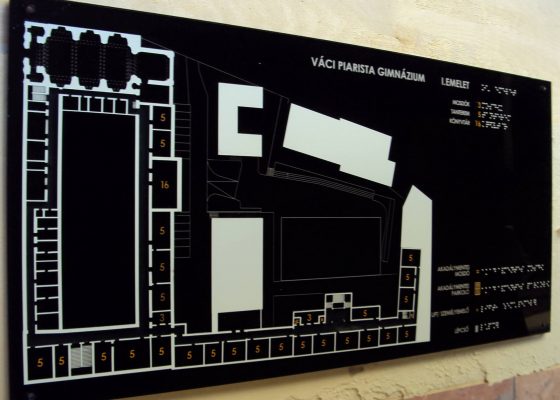

Laser cutting, laser engraving

WE ARE SPECIALIZED IN PRECISION CUTTING AND MARKING TECHNIQUES FOR WOOD, PLEXI, PAPER, LEATHER, TEXTILES AND MANY OTHER RAW MATERIALS.

CONTACT US WITH YOUR IDEA THROUGH OUR ONLINE SERVICE! UPLOAD YOUR VISION AND WE WILL CONTACT YOU!

If the file cannot be uploaded, please send us a Wetransfer link in the message section or contact us at info@limesmodel.hu! Thank You!

Process

UPLOAD

Send us your idea – preferably in an exact plan – drawn in an editable format (.PDF .SVG .DXF .DWG .CDR .AI .PLN .PLA) then we start negotiation and cooperation. We request the files as a ’Wetransfer link’ via our contact form.

CONTROL

We will review the uploaded files, contact you and send You a quote for the ordered product.

PRODUCTION

Once we have clarified all the issues and You have accepted our offer, we will start manufacturing the product quickly and accurately.

TAKEOVER

You can pick up the finished products in person at our office or we will deliver them to You by delivery service.

PLEX CUTTING, ENGRAVING

Plexiglas as a raw material can be cut very well with laser and is therefore an excellent choice for making small parts. The cutting edge stays completely clean, so we usually mask this material only if something extra surface treatment is later necessary (e.g. painting, sandblasting ..). It is also very easy to handle in terms of engraving. With an engraved surface and a little edge lighting, You can already get a good decor inscription. It can be layered, even with the use of several colors and thicknesses of plexiglass, it is a great shop decoration, it can be made into a company logo. Great choice for promotional materials, custom support systems, but even jewelry making.

In terms of thickness, it is worth considering load-bearing capacity and flexibility factors. Our machines are also able to cut 10 mm thick plexiglass sheets.

There are several colors and types of thickness (0.3, 0.5, 1, 2, 3, 4, 5, 6, 8, 10 mm) of raw materials in our warehouse, feel free to contact us with a specific idea or just a stray idea and we will help You choose the most suitable raw material for your project.

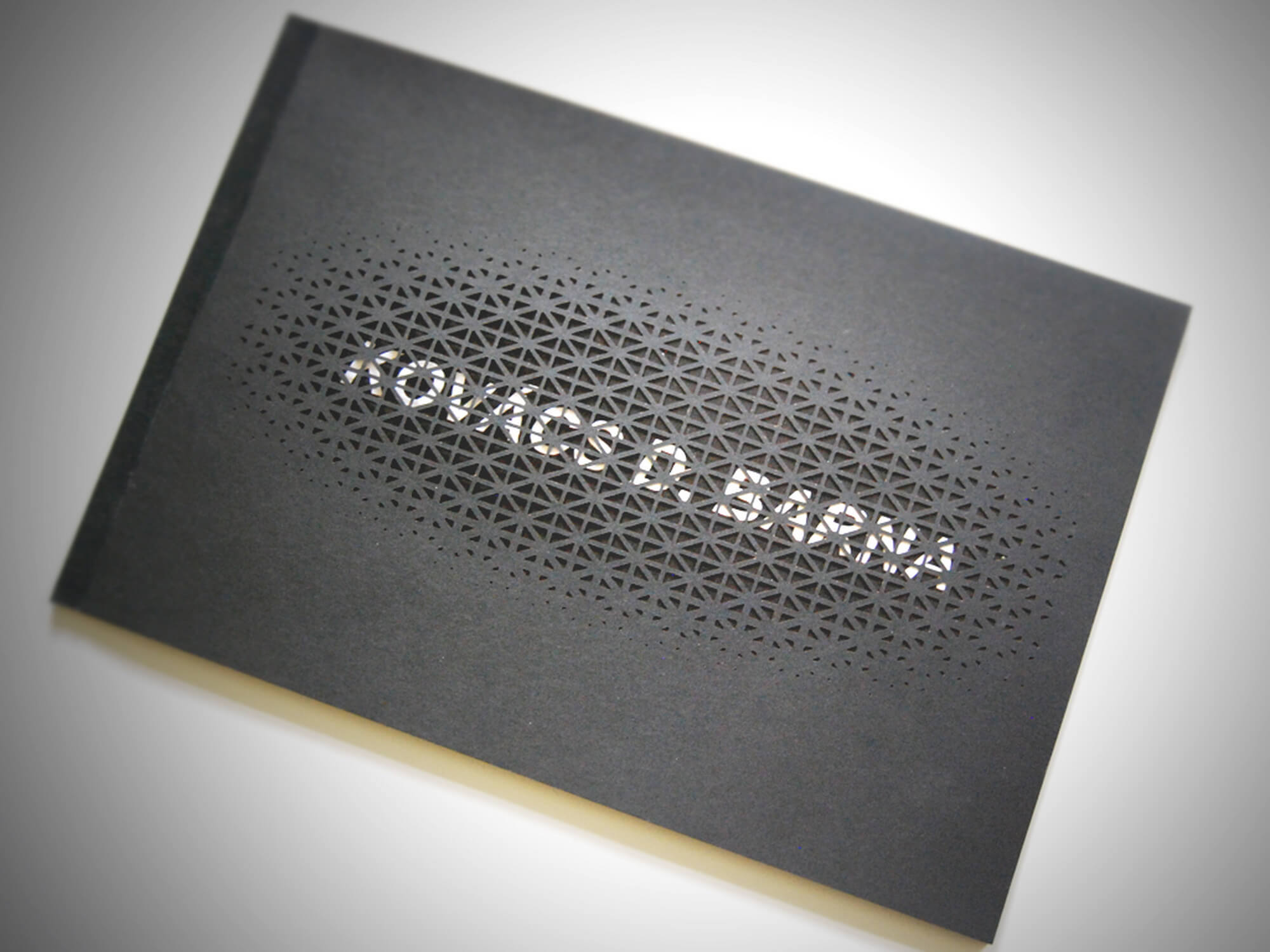

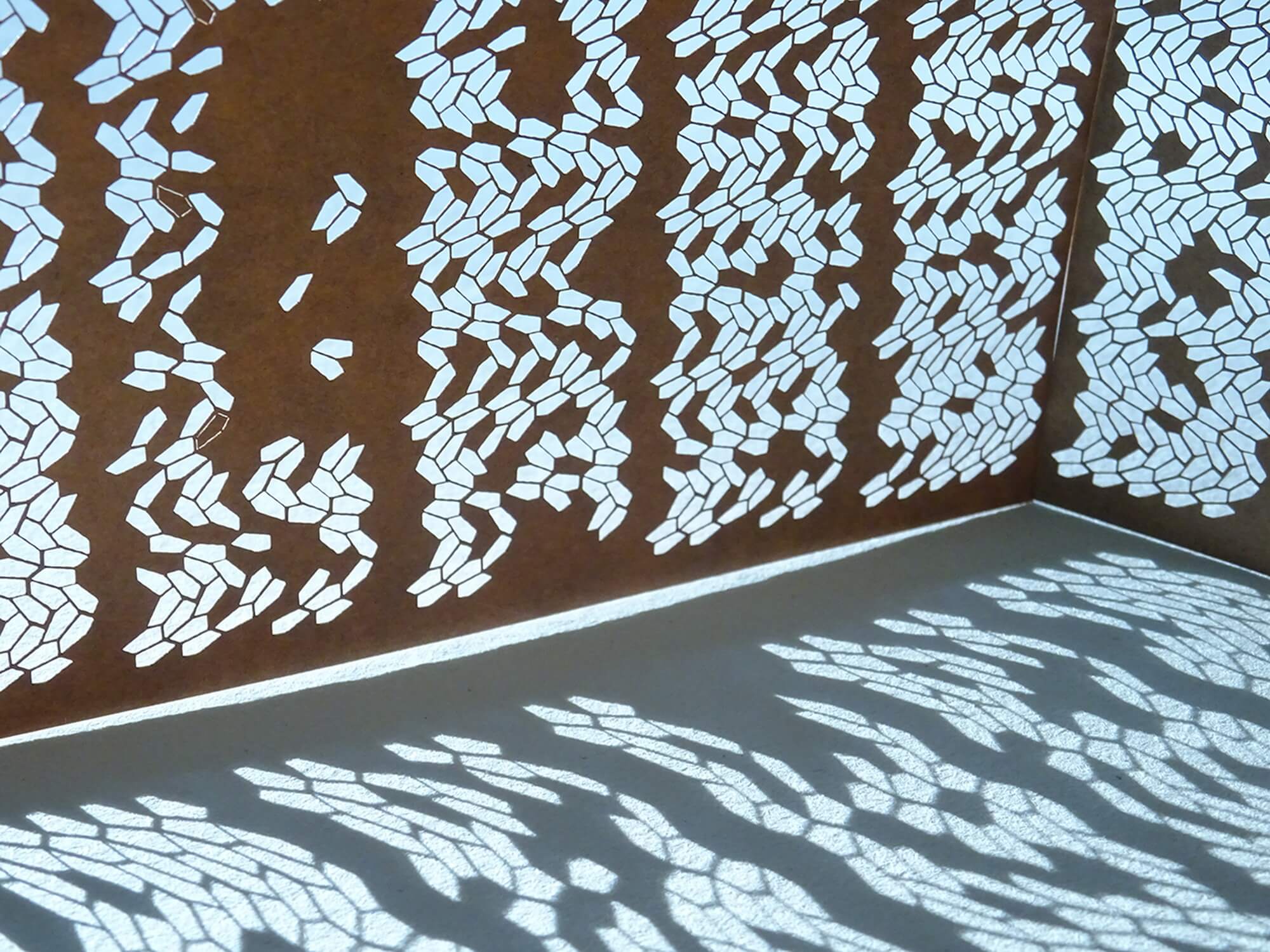

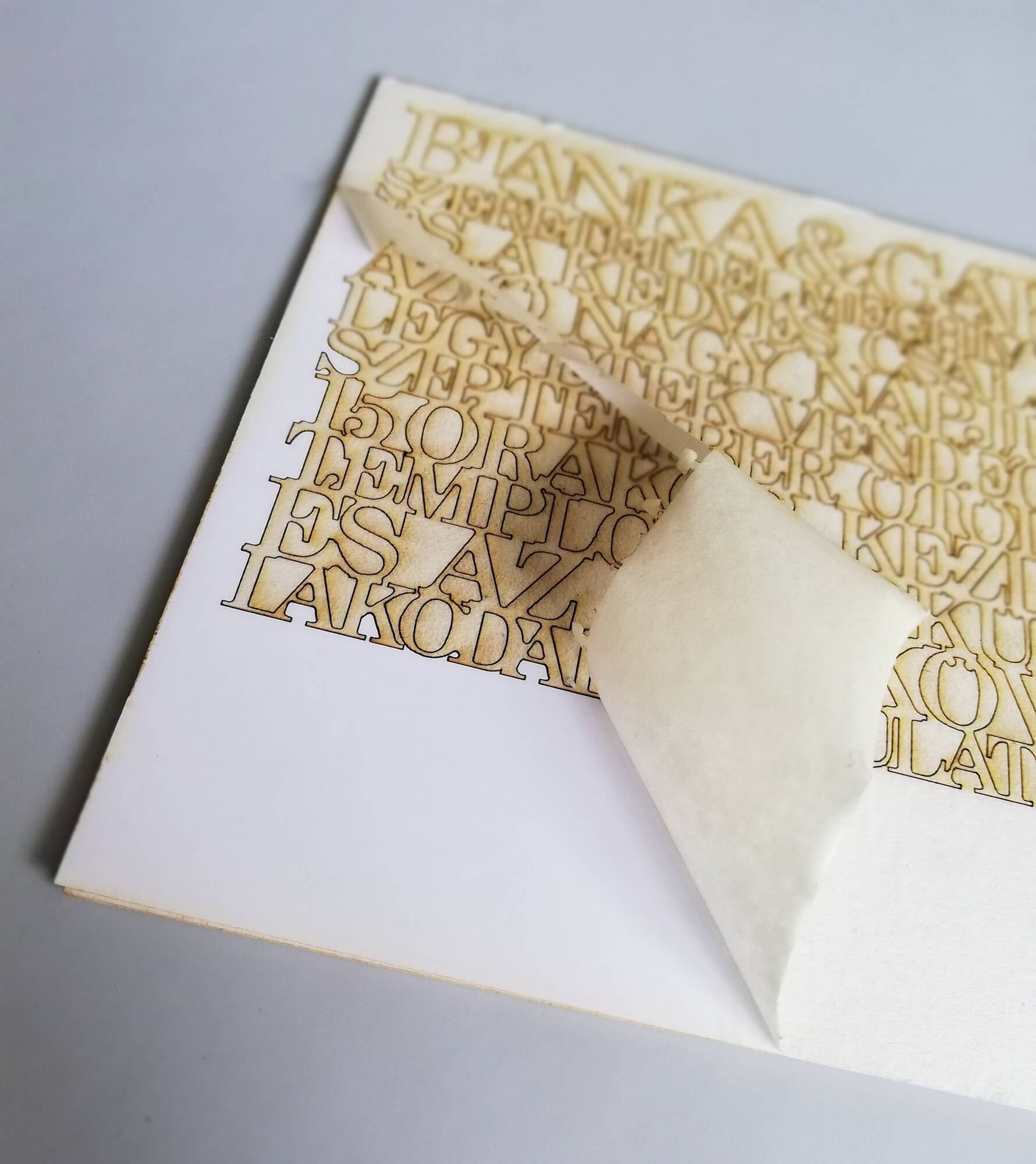

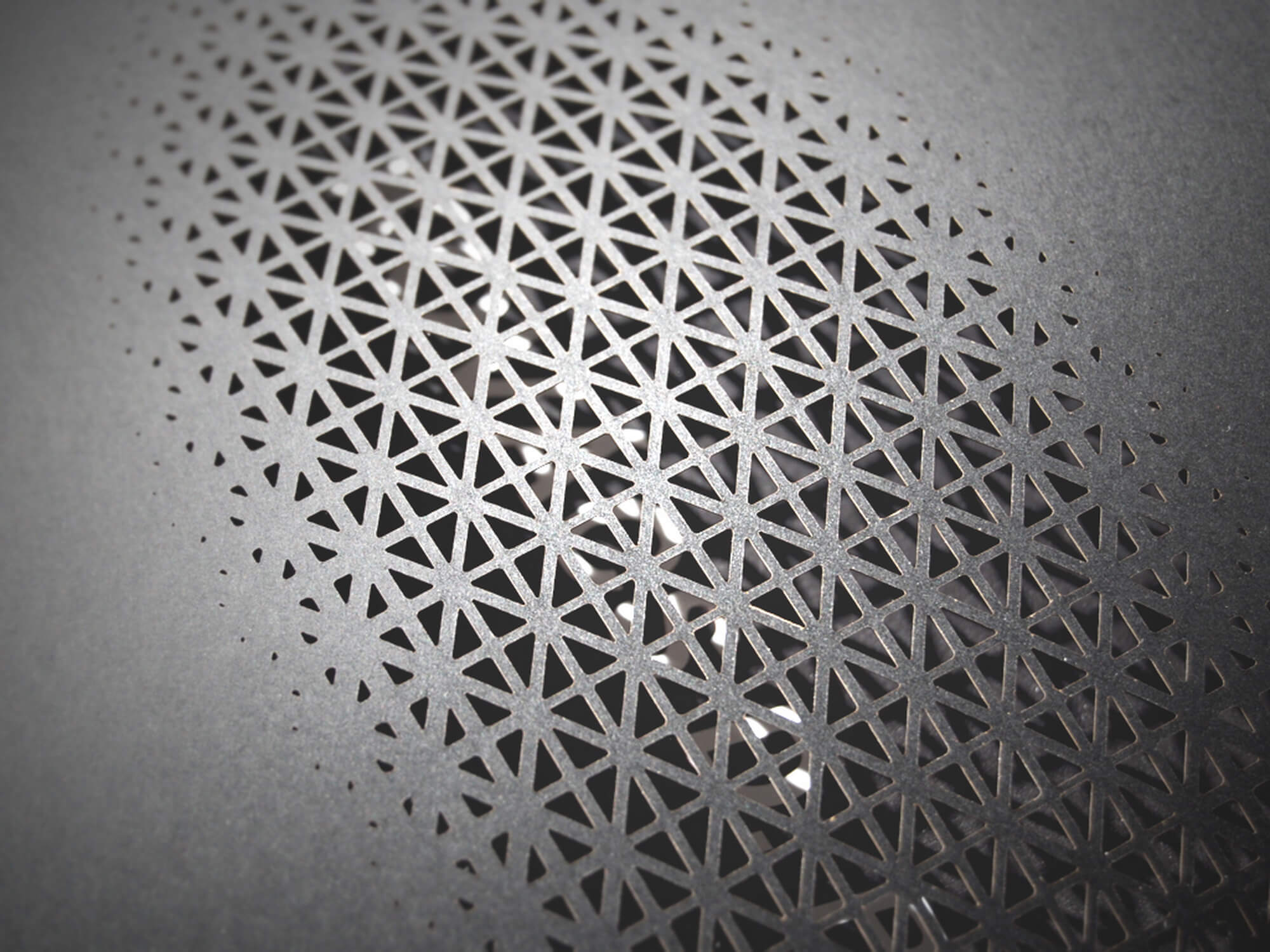

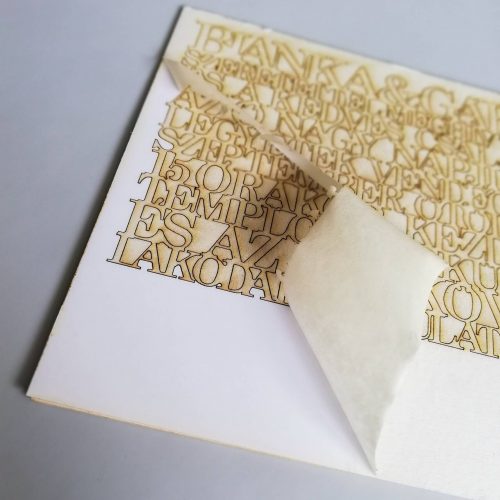

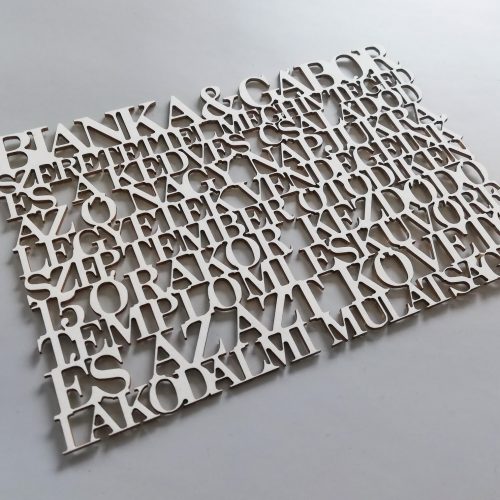

PAPER CUTTING, ENGRAVING

Laser makes paper a very nicely cut material, being also suitable for laser perforation and creasing. Depending on the variety, meticulous patterns can be cut out, so even lace patterned invitations, custom business cards, boxes, stencils can be produced. However, in many cases, as in the case of wood, the raw material can soot along the cutting edges, therefore it is often recommended that the production be carried out with masking if the finished product is not subsequently painted or treated. We work with several types and thicknesses of paper, from very thin decor paper to thick cardboard. Several groups of materials are kept in stock and we can undertake the procurement of raw materials for the order.

Paper is also a good raw material for engraving, but here the thickness and color are important, as not all materials will be high enough contrast. We recommended to make a production sample first.

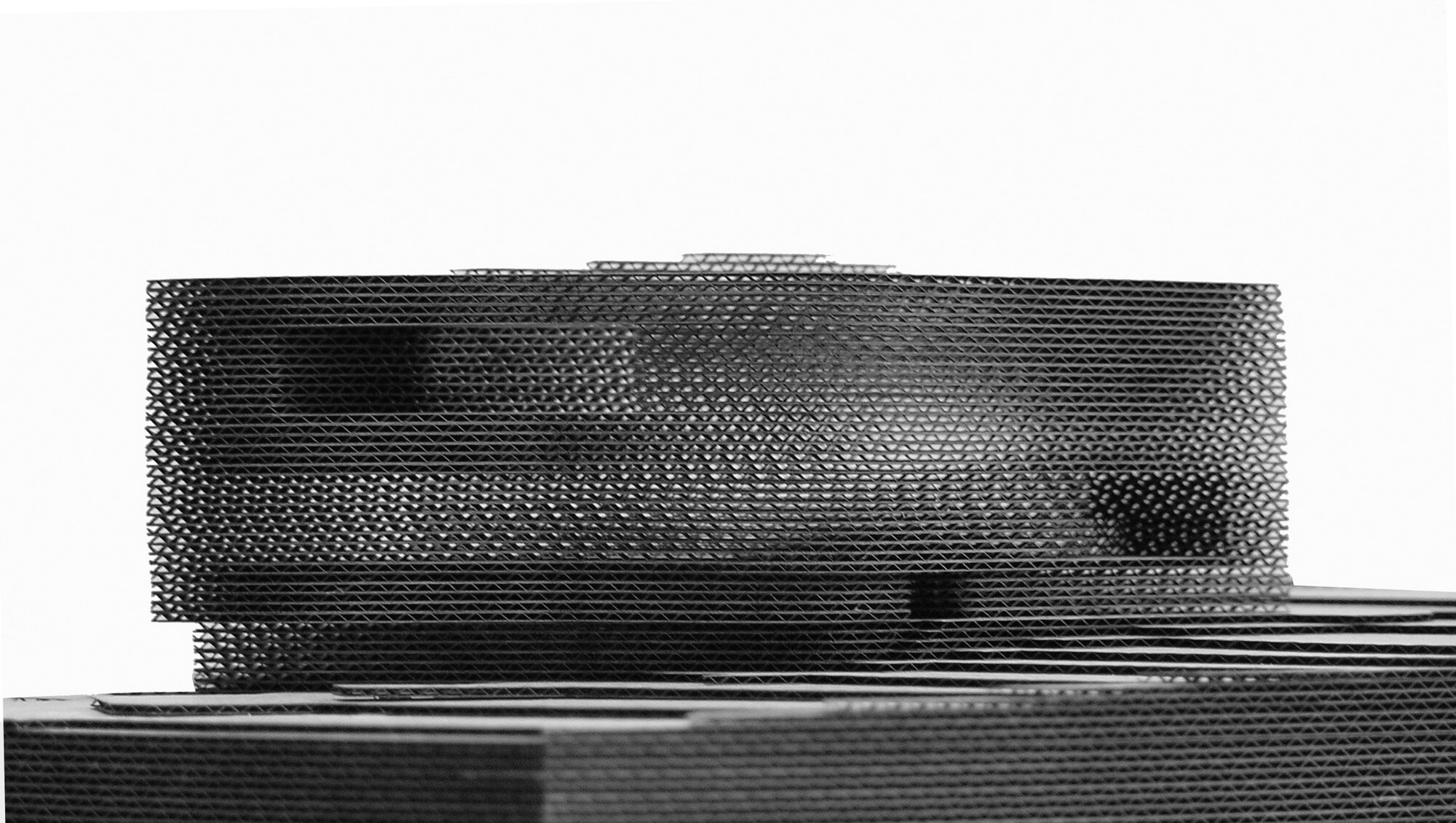

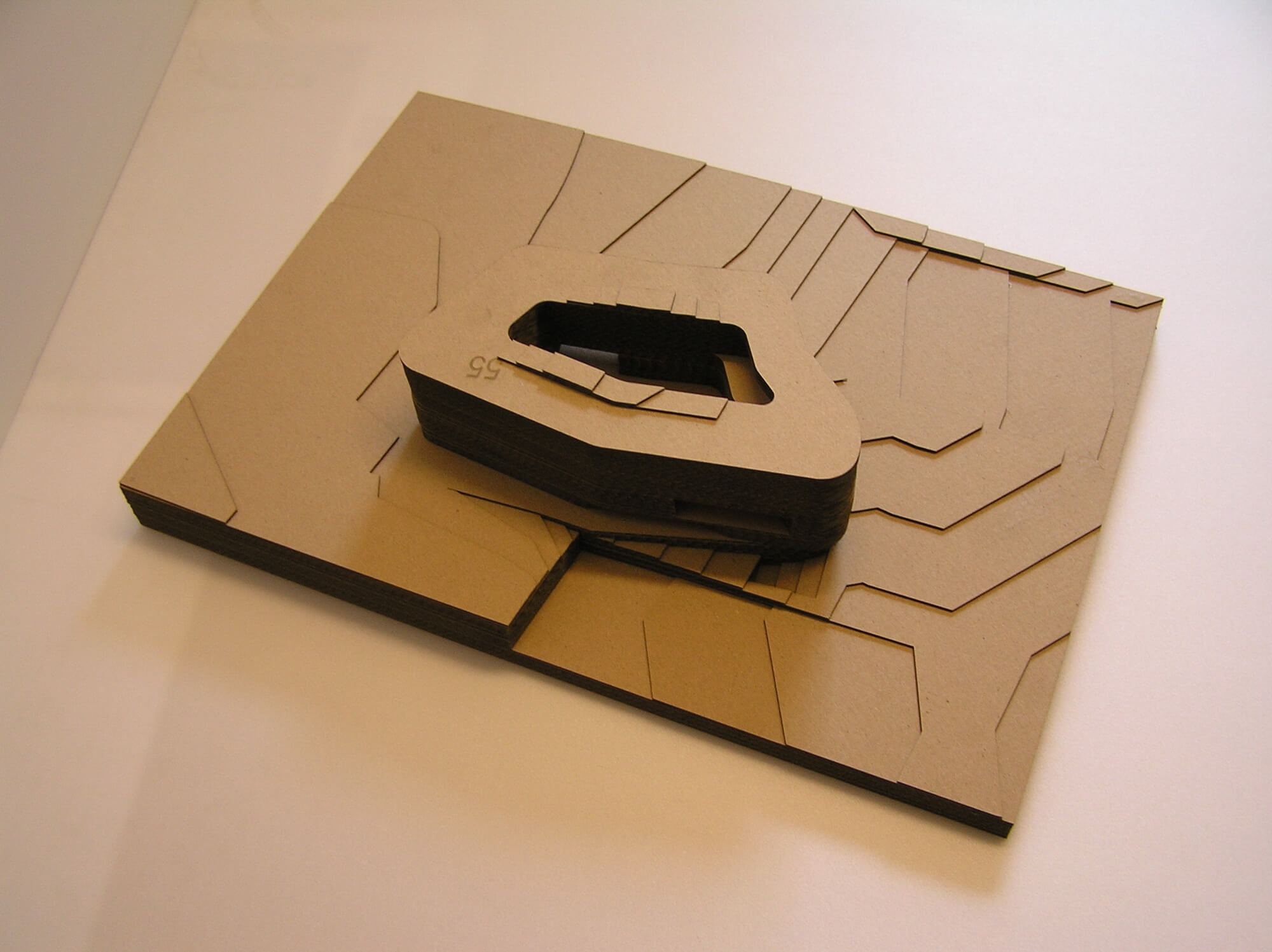

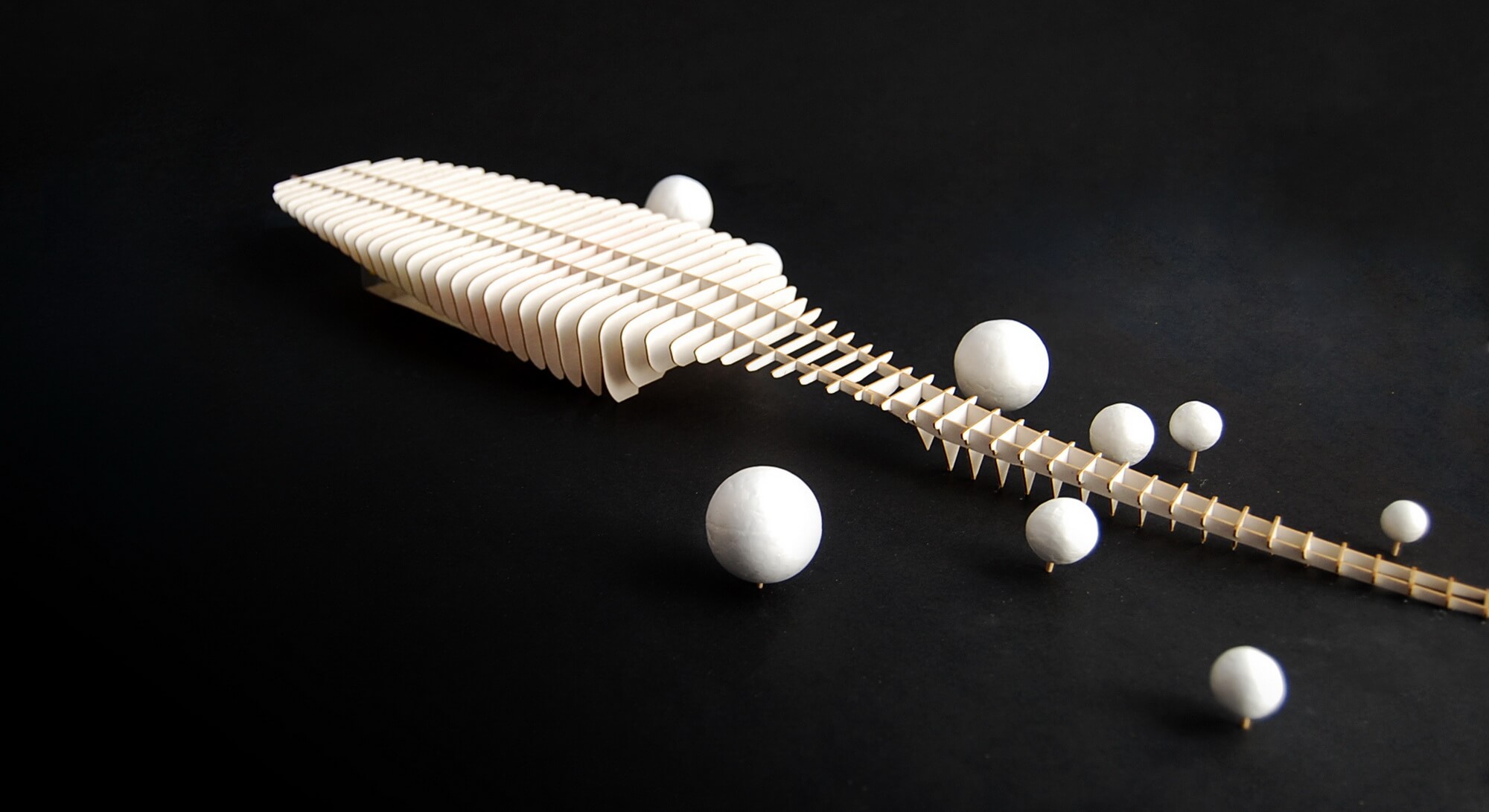

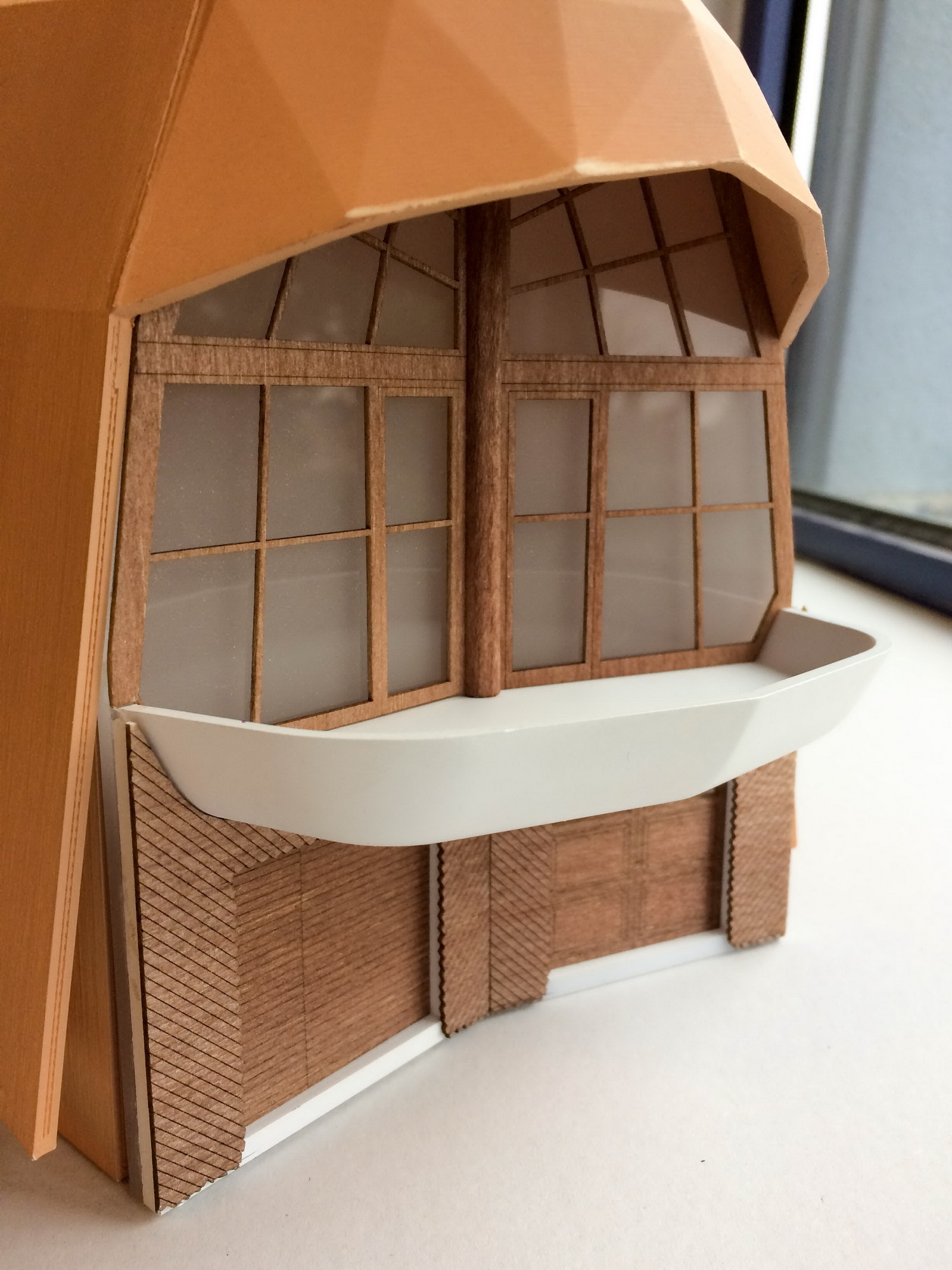

WOOD LASER CUTTING, ENGRAVING

Wood raw materials are usually well cut with laser. We also use in our work several different wood materials, such as veneer, balsa wood, plywood, and solid color wood. When cutting wood with laser, the cutting edge can be charred, the extent of which also depends on the thickness and type of wood. In this case, if a very accurate cut is on the need, we recommend a cut test. In the case a clean cutting image is required, masking is recommended, which protects the wood surface from sooting.

Wood is also a very good raw material in terms of engraving. With different strength settings, different depths and shades can be achieved, which vary from wood to wood. To achieve the desired effect, we usually recommend a production test.

Several type of materials are kept in stock and we can undertake the procurement of given raw materials, but we are also happy to work you’re your imported raw materials.

LEATHER & TEXTILE CUTTING, ENGRAVING

Leather can be cut particularly nicely with laser to a certain thickness. Detailed patterns and images can also be engraved on leather with the appropriate surface quality. The finer, smoother, and lighter the surface of the leather, the more beautiful results can be achieved. We have already made unique leather collars for puppies, but personalizing notebooks and wallets are no obstacles either. Textiles can be cut free of fringes and quickly with laser. Furthermore, certain materials such as jeans and velvet can even be engraved.

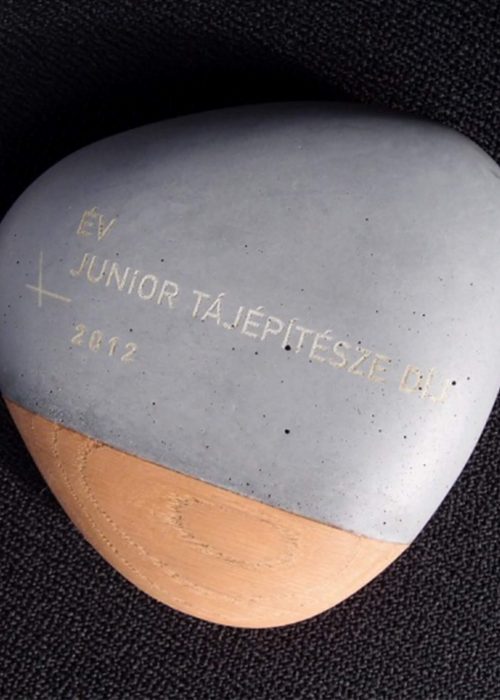

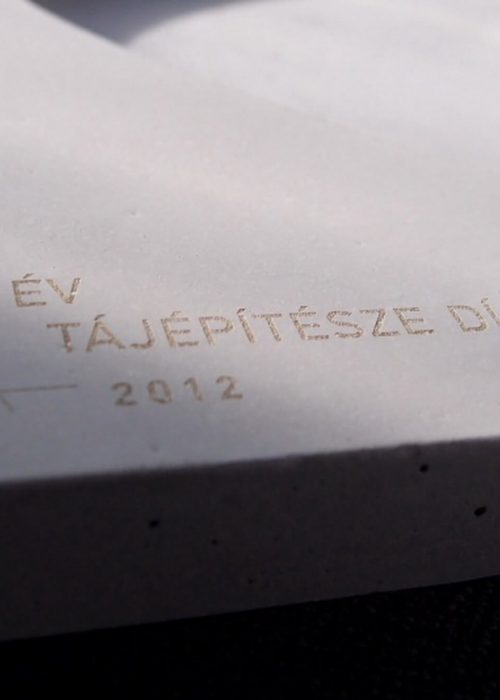

STONE AND CONCRETE LASER ENGRAVING

Like many other natural materials, stone, marble, and concrete can be engraved with laser, whether it’s for making inscriptions or taking pictures. The hardness of the base material itself determines the depth to which these engravings can penetrate the material. In general, we tend to recommend darker raw materials, as in our experience, laser engraving expands the surface rather than darkens it. However, we have also engraved on concrete slabs coated earlier at a festival, in which case the laser and paint layers are removed, and the color and text of the finished pattern are added to the base material.

SPECIAL MATERIALS

Limeslaser is a business branch of Limes Model Ltd., which is specialized in modeling. As a result, several raw materials are kept in stock which are specialized for modelers but easily accessible for other customers also. Knowledge of these materials allows us to offer our customers a potentially better, more suitable raw material for some individual projects, not just for making mockups.

Examples are a wide range of prespan boards, cover boards, styrene, and paper vinyl sheets. They are all well cut with a laser, perfect ingredients for making tiny parts with great meticulousness. We also laser cut sandpaper and artificial grass, as well as masking material.

STAMP MAKING

Our company undertakes the production of stamps, be it a corporate or signature stamp, wedding accessories or an Ex libris imprint. Making self-inking stamps, or even embossing, is not a problem at all. Today, it is a proven and widespread way to personalize either your own business card or corporate packaging.

MASKING

As dust, glue or resin escaping from certain raw materials during laser cutting can contaminate and matt the product along the cut, we often recommend masking to our customers. There are projects where it is important that the cut edge is completely clean and free of fog. In this case, a thin paper-based masking layer is glued on it, which can be easily removed after cutting, leaving a completely clean surface. However, if the product is subsequently sanded, painted or subjected to other surface treatments, this is not necessary for you. There are projects in which the masking layer is used and cut on the base material precisely because only a part of the product will be surface treated. It can also be a simple solution for making painted boards and parts.

Hajnalka Vargova,

LASER AND CNC BUSINESS LEADER

+36 20 372 3695

info@limeslaser.hu